Packaging & Printing

Polypropylene (PP) Strap

Price upon request

Polypropylene (PP) Strap

Polypropylene is the most commonly used and least expensive of all Packaging straps. It is lightweight and easy to apply. Polypropylene is available in both manual and machine grades and can be sealed with buckles, seals, heat sealing, or friction welding.

Polypropylene is an excellent choice for light-duty palletizing, unitizing, carton closing, and bundling. It is used in all semi-automatic strappers and many stand-alone arch machineries. PP strapping is available in several variants- attractive colors, plain, printed, etc. Available for fully automatic, semi-automatic, and manual applications.

Features of VIR Polypropylene (PP) Straps:

- Best suitable for light to medium-duty application.

- Clear performance on all types of machines.

- Uniform surface to keep strap tight

- Most Economical plastic strapping

- Saves cost

- Light in weight

- Heat sealable by manual/ automatic strapping tools

- Elongates 5-10% to withstand stress and resists shock

- Impervious to rust

- Safer to use. No sharp edges eliminates backlash

Price upon request

Steel Strap

Price upon request

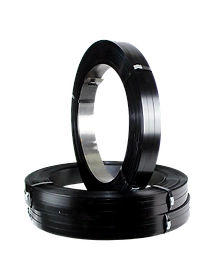

Steel Strap

Vir offers two basic types of steel strapping: VirSuper and VirUni.

Each is specially formulated to meet the demands of a particular range of applications. And for each strapping type, there is a selection of sizes and finishes which matches

the specific requirements of those applications.

VIRSUPER STRAPPING

A cold-rolled, medium carbon steel strapping. Heat-treated with a process that combines fine surface and controlled physical properties with high strength and excellent shock resistance.

VIRUNI STRAPPING

A cold-rolled, low carbon steel strapping. Manufactured with superior edge conditioning and coating. Most standard packaging applications use VirUni strapping.

Painted and waxed

Painted and waxed strapping provides corrosion resistance.

Price upon request

Packing Desiccant

3.00

Packing Desiccant

PURPOSE

To protect a myriad of goods from costly damage by adsorbing excess moisture during shipping and storage.

WHAT ARE THEY?

Desiccant Bags are essentially desiccants packaged in porous materials that allow them to effectively absorb moisture inside packaging or storage containers to protect any number of products, including semiconductors, electronic devices, food, equipment, machinery, military goods, metal components and many other valuables.

WHY USE THEM?

Moisture can quickly affect the value or even destroy many types of valuable goods, causing rust, corrosion, mildew, mold and device malfunction. By sealing goods inside packaging with the appropriate desiccant, goods can be protected from moisture and maintain long shelf lives.

3.00

Container Desiccant

Price upon request

Container Desiccant

PURPOSE

To protect cargo from the harmful effects of moisture damage during shipping via container, rail, or truck.

WHAT IS IT?

Container Dri II is a line of specially designed cargo desiccants aimed at protecting cargo during shipping by aggressively absorbing moisture from the air. In doing so, Container Dri II reduces dew point temperature (the temperature at which condensation begins to form, causing “container rain”), keeping cargo safe and dry. The Container Dri II line includes several configurations to best fit different needs and modes of transport and carries the Clariant EcoTain label for products with outstanding sustainability advantages.

WHY USE IT?

As goods move through intermodal systems, they are susceptible to damage from excessive moisture. Container Dri II adds a level of protection by reducing dew points to avoid the accumulation of condensation. Container Dri II absorbs up to three times its weight in moisture, and through an advanced formula, traps it as a thick, no-spill gel. Container Dri II has the ability to protect shipments from start to finish, through all temperature ranges and relative humidity variances, and continues to reduce the relative humidity down to levels below 40 percent RH, which decreases the dew point temperature even further.

Price upon request

PET Strap

Price upon request

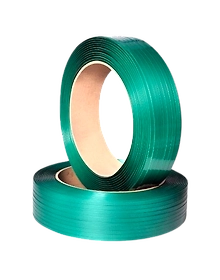

PET Strap

VIR PET STRAPS REDUCE DAMAGES WHILE TRANSPORTING YOUR VALUABLE GOODS.

FEATURES OF VIR PET STRAPS:

• High retained tension

• Good shock absorption

• No-load damage

• Significant less safety hazard

• PET does not rust

• Good environment resistance

• Easy Recycle

• No seal required

• Printing is possible for Branding

Price upon request